Introduction

Indian textiles are a living archive of techniques, trade routes, ritual aesthetics, and regional identities—ranging from lustrous silk sarees to painstaking hand-block prints. Across centuries, artisans have refined dyeing, weaving, printing, and finishing processes that marry utility with art. From Harappan-era traces of dyed cotton to Mughal-era design sophistication and today’s eco-conscious revivals, the subcontinent’s textile story weaves continuity and change into every yard of cloth.

Civilizational Roots and Mughal-Era Flourish

Archaeological anchors: Indus Valley finds include cotton fibers dyed with madder, needles, and spindles—evidence of mordanting and early dye mastery.

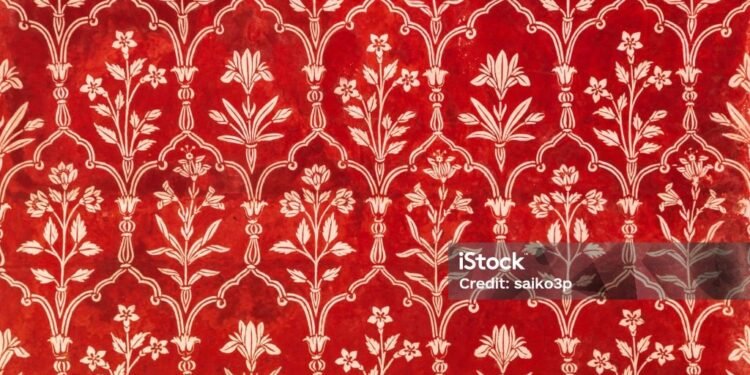

Mughal momentum: Under Mughal patronage, printing and dyeing aesthetics matured, with centers in Rajasthan and later Gujarat shaping block-printed fabrics that traveled widely in trade and taste.

The Craft of Hand-Block Printing

The long making: Typical lead times of 10–15 days reflect a multi-stage process—desizing and washing, sun-drying, table pinning, color preparation, registration printing, staged drying, steaming, washing, and final pressing.

Blocks and dyes: Intricately carved wooden blocks (teak, sycamore, pear) are soaked in oil 10–15 days for durability before use; pigments are mixed with binders on cushioned trays for even pick-up and transfer.

Register and rhythm: Each color demands a dedicated block and precise alignment; artisans wait for layers to dry before overprinting, ensuring crisp motifs and continuous repeats along the fabric length.

Printing Techniques: Direct, Resist, Discharge

Direct printing: Fabric is bleached, dyed, then printed with carved blocks in sequential colors.

Resist printing: Select areas are shielded with clay/resin pastes before dyeing; subsequent washing reveals protected patterns, often with ripple effects in the field.

Discharge printing: Chemicals remove color from pre-dyed cloth; the discharged zones are then over-dyed, enabling light motifs on dark grounds with sharp definition.

Regional Lineages and Signature Styles

Rajasthan to Gujarat and beyond: Historical cores in Rajasthan and Gujarat expanded to active hubs across West Bengal, Andhra Pradesh, Punjab, Maharashtra, Madhya Pradesh, and Uttar Pradesh—each adapting motifs and palettes to local taste and supply chains.

Classic vocabularies: Bagru’s earthy mordant/resist looks, Sanganeri’s fine floral bootis, indigo-rich Dabu resist prints, Ajrakh’s complex double-sided geometries, and Kalamkari’s block-and-pen narrative textiles illustrate India’s print diversity.

Motif canons: Florals, jaal networks, paisleys, butis, and Mughal-inspired bouquets; animal forms like elephants; and ornamental borders synchronize across sarees, dupattas, and yardage.

Silk Sarees and Printed Tussar

Tussar’s character: Wild silk with a textured hand and warm sheen receives block prints beautifully, pairing drape with design depth—a reason printed pure silk sarees remain prized for festive and daily elegance.

Color and care: Layered printing on tussar demands careful post-print steaming, washing, and pressing to lock in hues and stabilize the cloth’s hand, ensuring long-term vibrancy.

Sustainability, Labor, and the Human Touch

Imperfect charm: Hand processes introduce subtle variation—micro-shifts in registration, dye pooling, and woodgrain impressions—that create “alive” surfaces unattainable by full automation.

Eco-forward practice: Natural/organic dyes, low-energy sun-drying, long-lived wood blocks, and water-conscious workflows align heritage with contemporary sustainability goals.

Disruption and Revival

Colonial contraction: Heavy taxes on Indian textiles under British rule undermined village production; many artisans left for urban mills, fracturing transmission lines.

Post-independence renewal: Government schemes, design institutes (NID, NIFT), and designer–artisan collaborations re-energized the sector, connecting workshops to modern markets and audiences.

Inside the Atelier: A Maker’s Workflow

Pre-press: Desize and scour; sun-dry; tension and pin cloth on long tables.

Ink kitchen: Mix pigments with binders; stage trays for even loading; test impressions for clarity and edge fidelity.

Printing: Align repeat; stamp base color; dry; layer secondary and accent colors with dedicated blocks; check for breaks and overlaps; correct minimally to preserve hand.

Finishing: Sun-dry; steam for fixation; wash to release unbound dye; sun-dry again; final iron and quality check for motif integrity and colorfastness.

Contemporary Design: Heritage, Refined

Hybrid aesthetics: Brands pair classical jaals, bootis, and Mughal florals with modern scale and placement—engineered pallus, border play, and negative-space layouts that flatter drape and silhouette.

Ethical retail: Provenance labeling, fair pricing, and GI-conscious messaging help consumers back artisan clusters and safeguard intangible heritage in an era of mass replication.

How to Read and Care for Block-Printed Textiles

Reading the cloth: Look for repeat registration, layered color edges, and grain of the block; slight shifts indicate handwork, not defects.

Care basics: Gentle hand-wash in cold water for silks; shade-dry to protect dyes; avoid harsh detergents; low-heat pressing on reverse preserves both fiber and print.

Conclusion

From the earliest mordanted cottons to today’s eco-conscious, block-printed silks, Indian textiles prove that technique and storytelling can share the same warp and weft. The artisan’s measured hand—mixing color, aligning block, lifting breath between stamps—turns fabric into culture. Each motif and border is not just pattern but practice, connecting Harappan dye vats, Mughal gardens of design, and contemporary studios that keep this heritage both rooted and resonant.